Explore More

Bio Ethanol Production

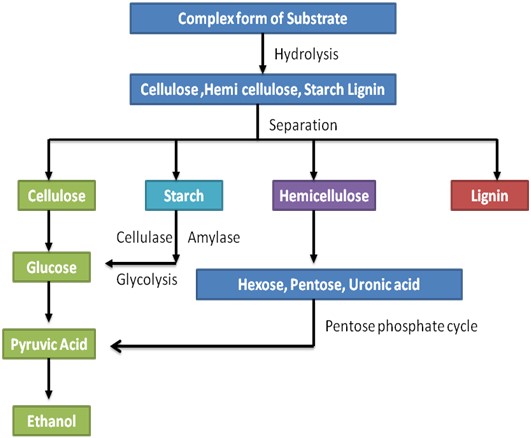

Commercial bio-ethanol is currently produced from starch/ sugar-based crops including sugar cane, sugar beet, sweet sorghum, corn, wheat, barley, potato, yarn, and cassava. One commercially-practiced technology is to produce ethanol by fermenting plant biomass derived simple sugars (i.e., glucose, fructose, and other mono saccharides). The problem lies with the use of this biomass for ethanol production is it’s pretreatments to obtain simple sugars that are bind with hemicellulose and lignin. Research has been intensively conducted to develop effective pretreatment methods for obtaining simple sugars from lingo-cellulosic materials such as sweet sorghum, Cassava, elephant grass, suger beets etc.

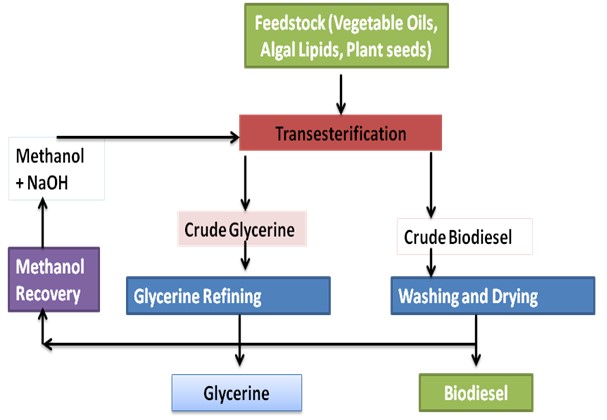

The oils obtained from the above said substrates cannot be used as a fuel directly because of some impurities it posses such as free fatty acids, sterols, phospholipids, water, odour etc. To overcome these problems there are some chemical modifications are required like transesterification, pyrolysis and emulsification.

Process involved in bio-ethanol production

Pre treatment process

Pre treatment is used to remove the lignin and there are several pretreatment methods:- Concentrated Acid Hydrolysis Process, Dilute Acid Hydrolysis , Enzymatic Hydrolysis, Wet Milling Processes, Dry Milling Process.

Saccharification Process

It’s a enzymatic hydrolysis processes where cellulase enzyme degrade the cellulose to sugar. Cellulase producing common fungi are Aspergillus niger, Trichoderma reseesi used for cellulose degradation and further this sugar go for fermentation.

Sugar fermentation Process

The hydrolysis process breaks down the cellulostic part of the biomass into sugar solutions that can then be fermented into ethanol. Yeast is added to the solution, which is then heated. The yeast contains an enzyme called invertase, which acts as a catalyst and helps to convert the sucrose sugars into glucose and fructose (both C6H12O6).

Fractional distillation process

The ethanol, which is produced from the fermentation process, still contains a significant quantity of water, which must be removed. This is achieved by using the fractional distillation process. The distillation process works by boiling the water and ethanol mixture. Since ethanol has a lower boiling point (78.3C) compared to that of water (100C), the ethanol turns into the vapour state before the water and can be condensed and separated.